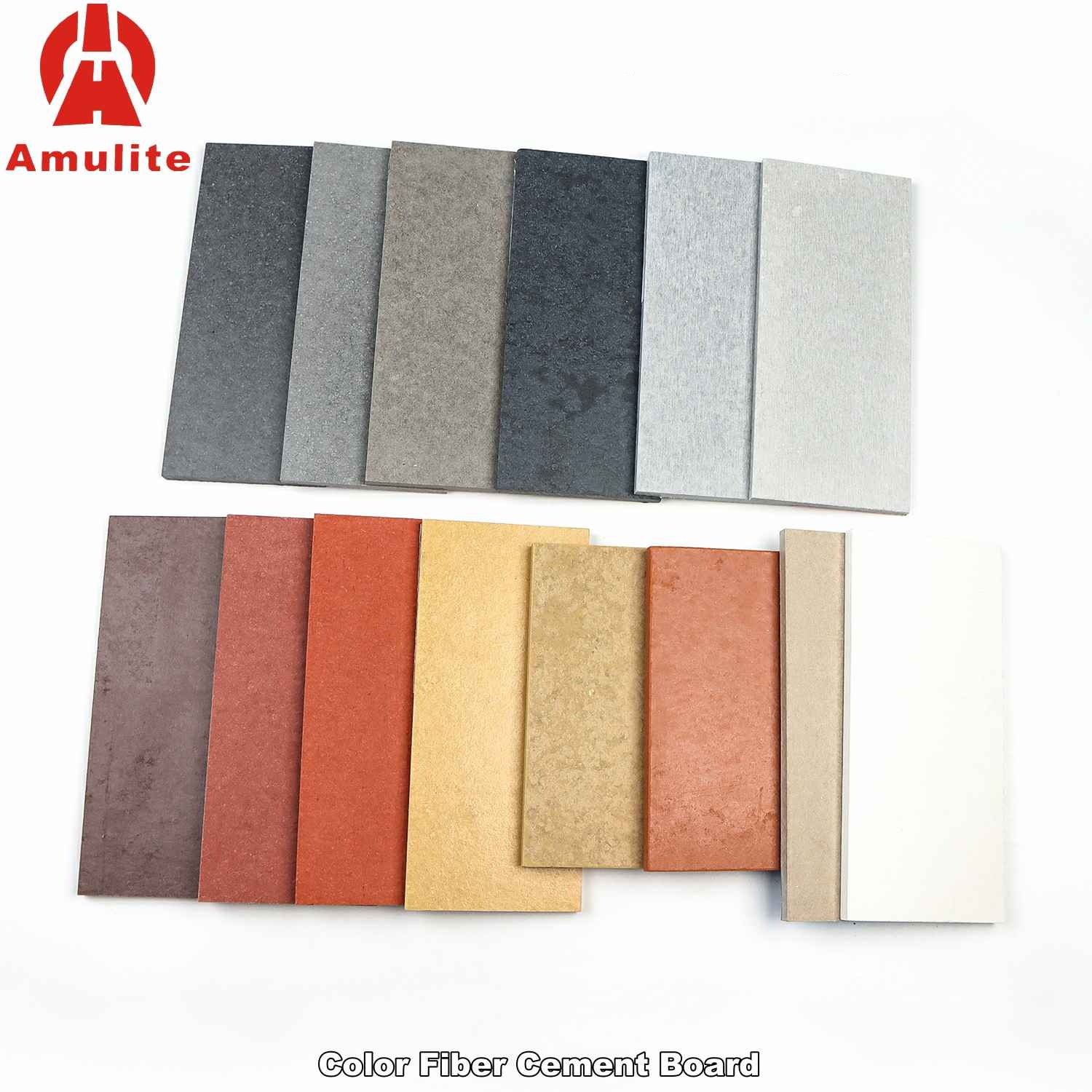

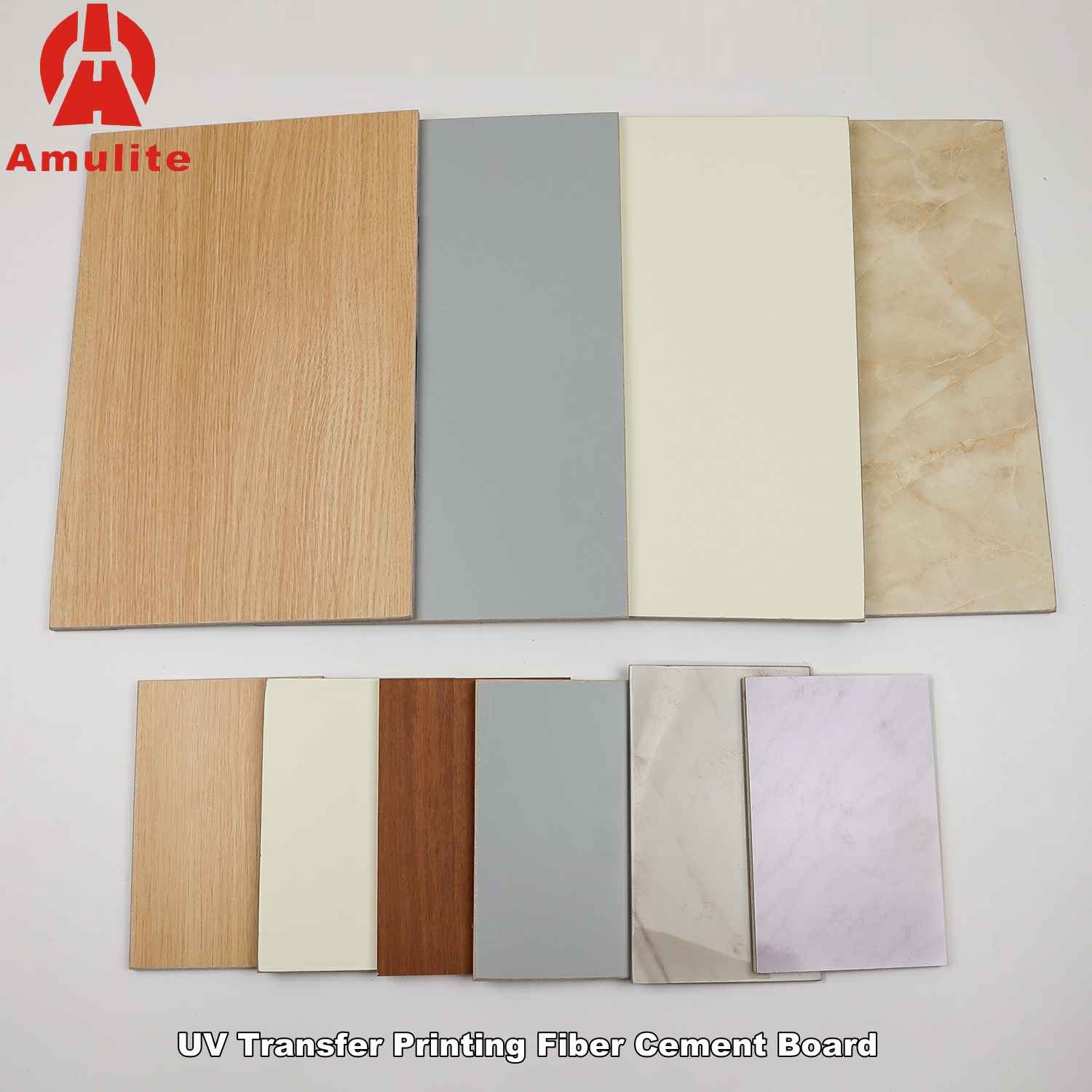

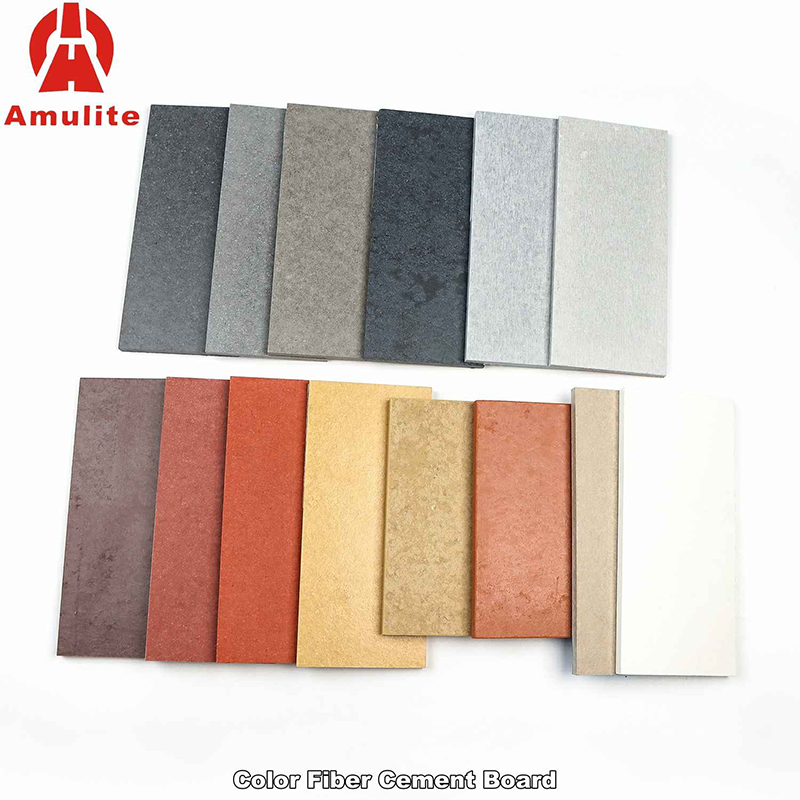

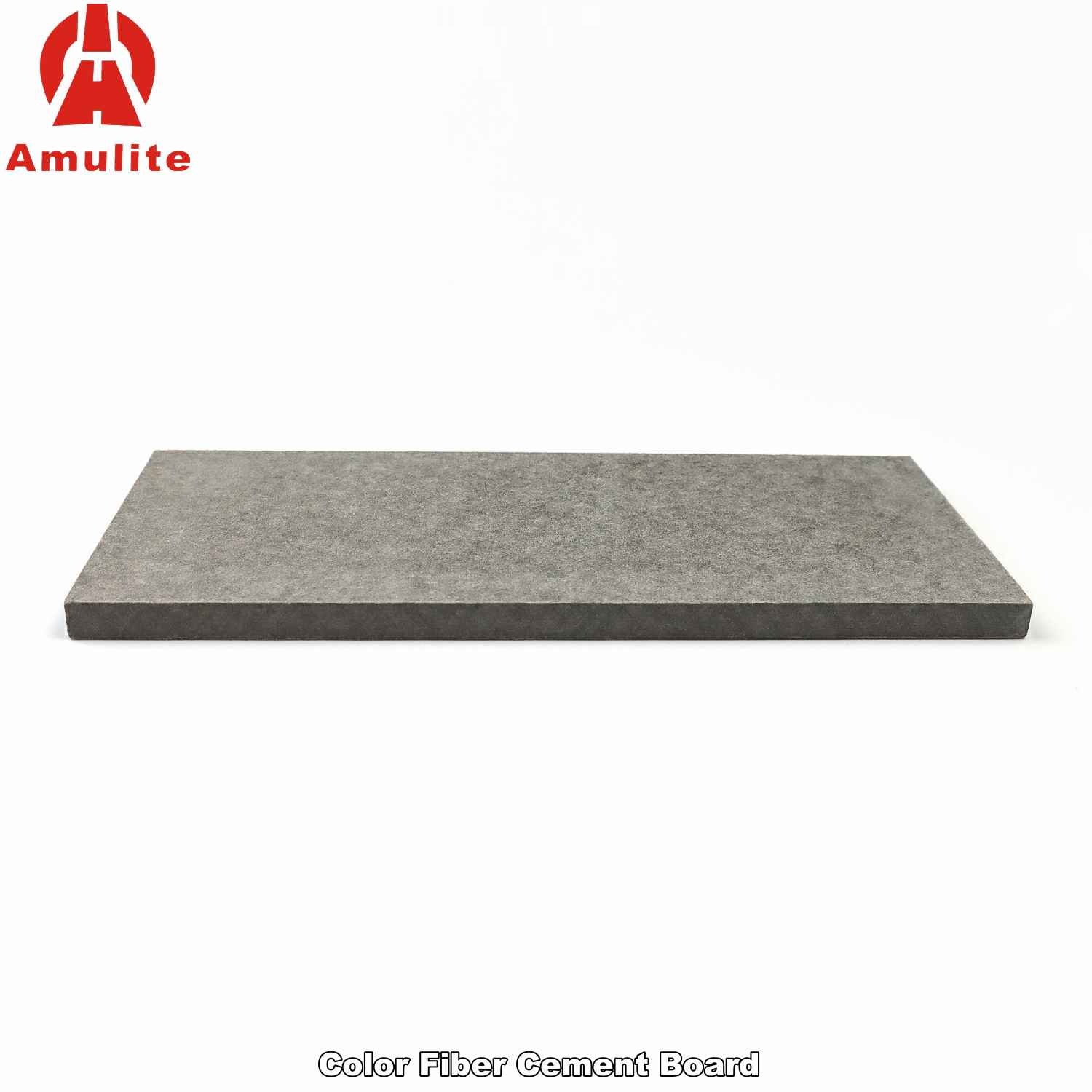

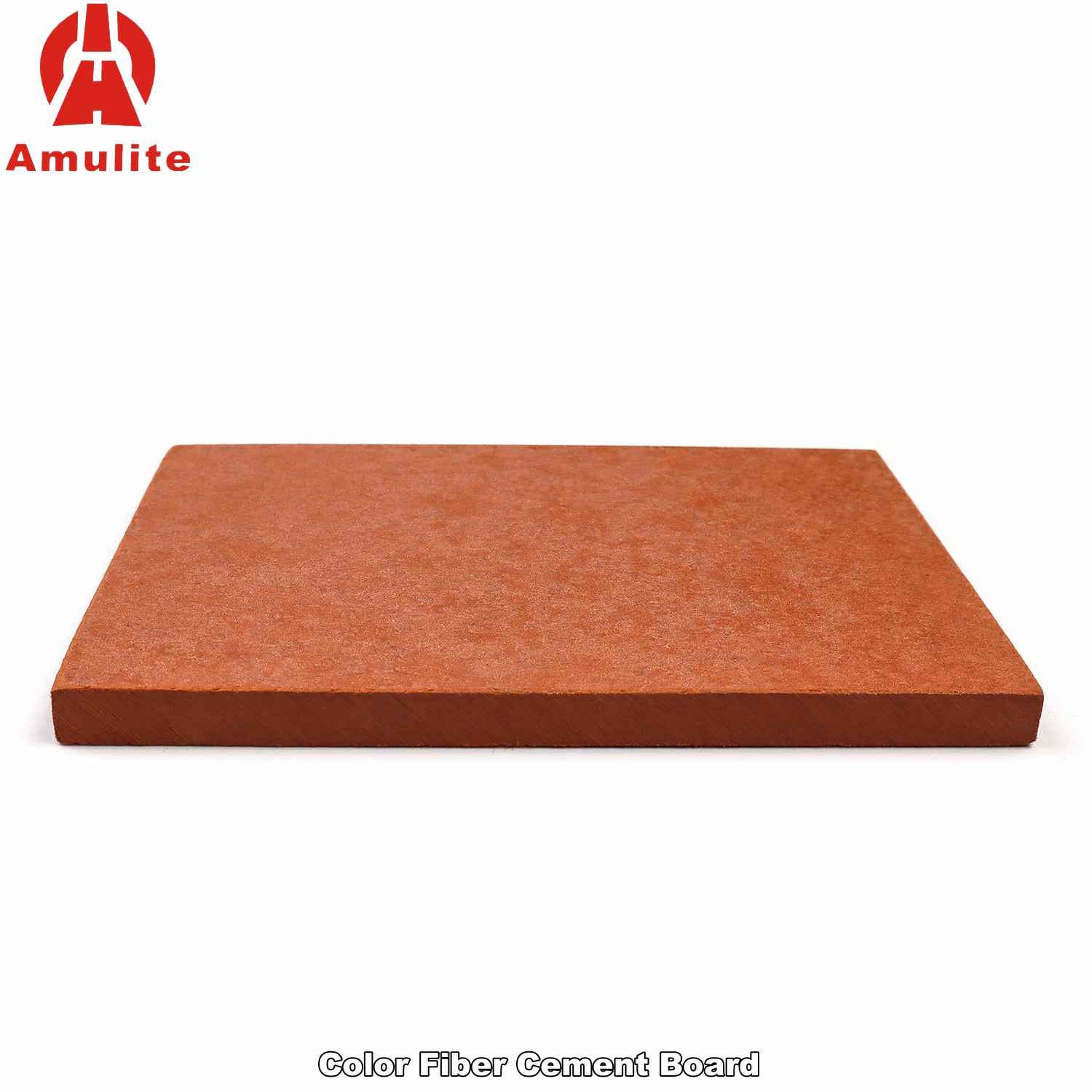

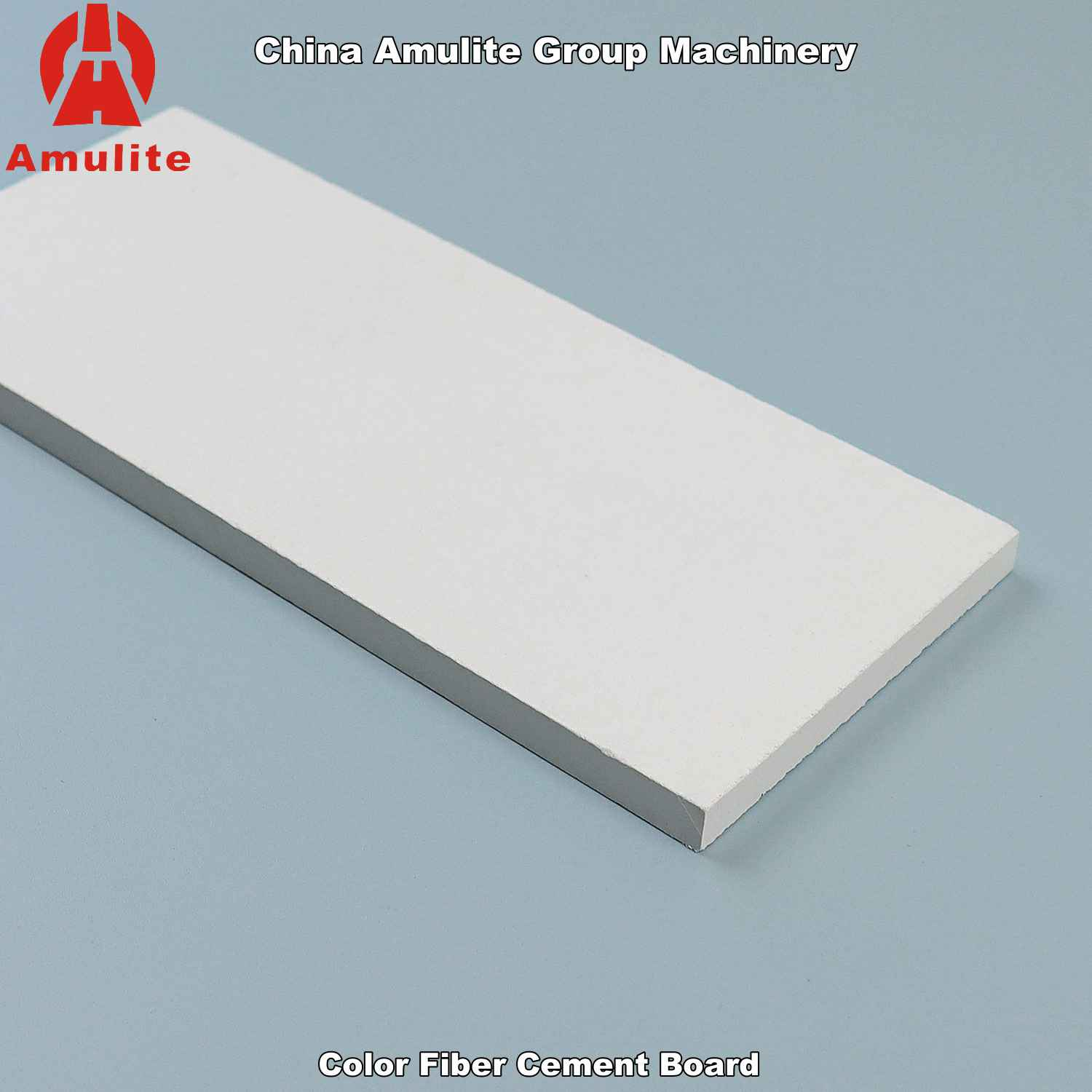

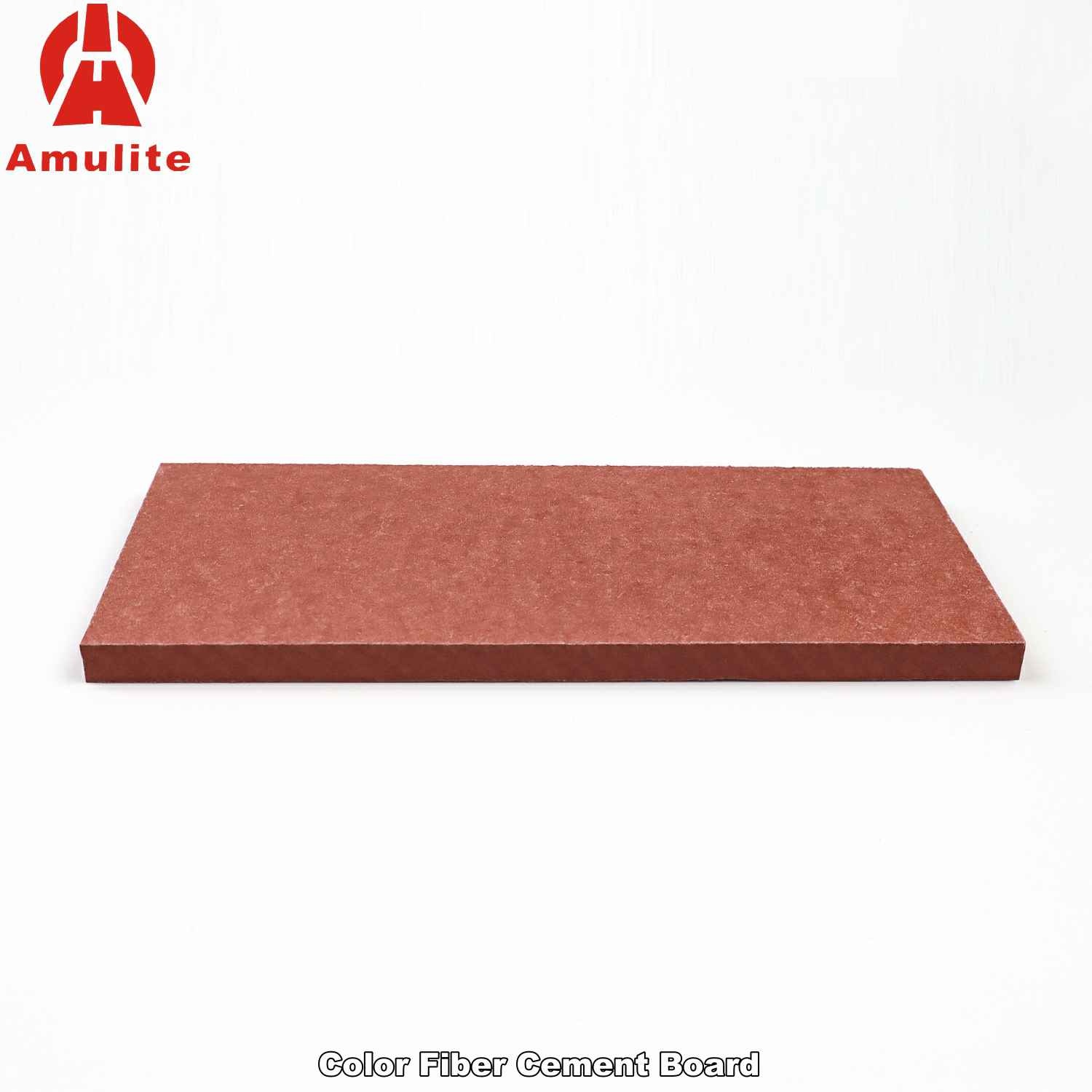

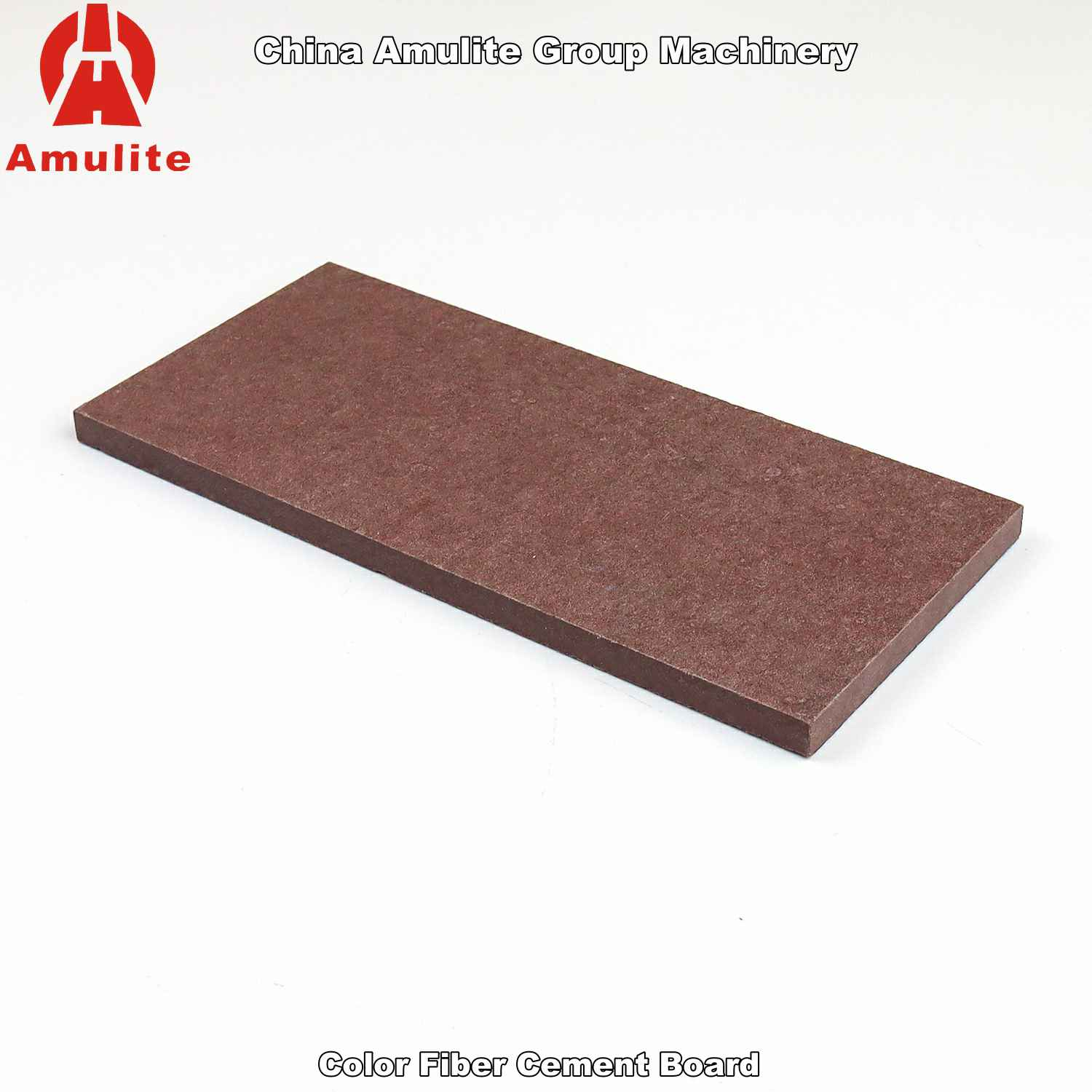

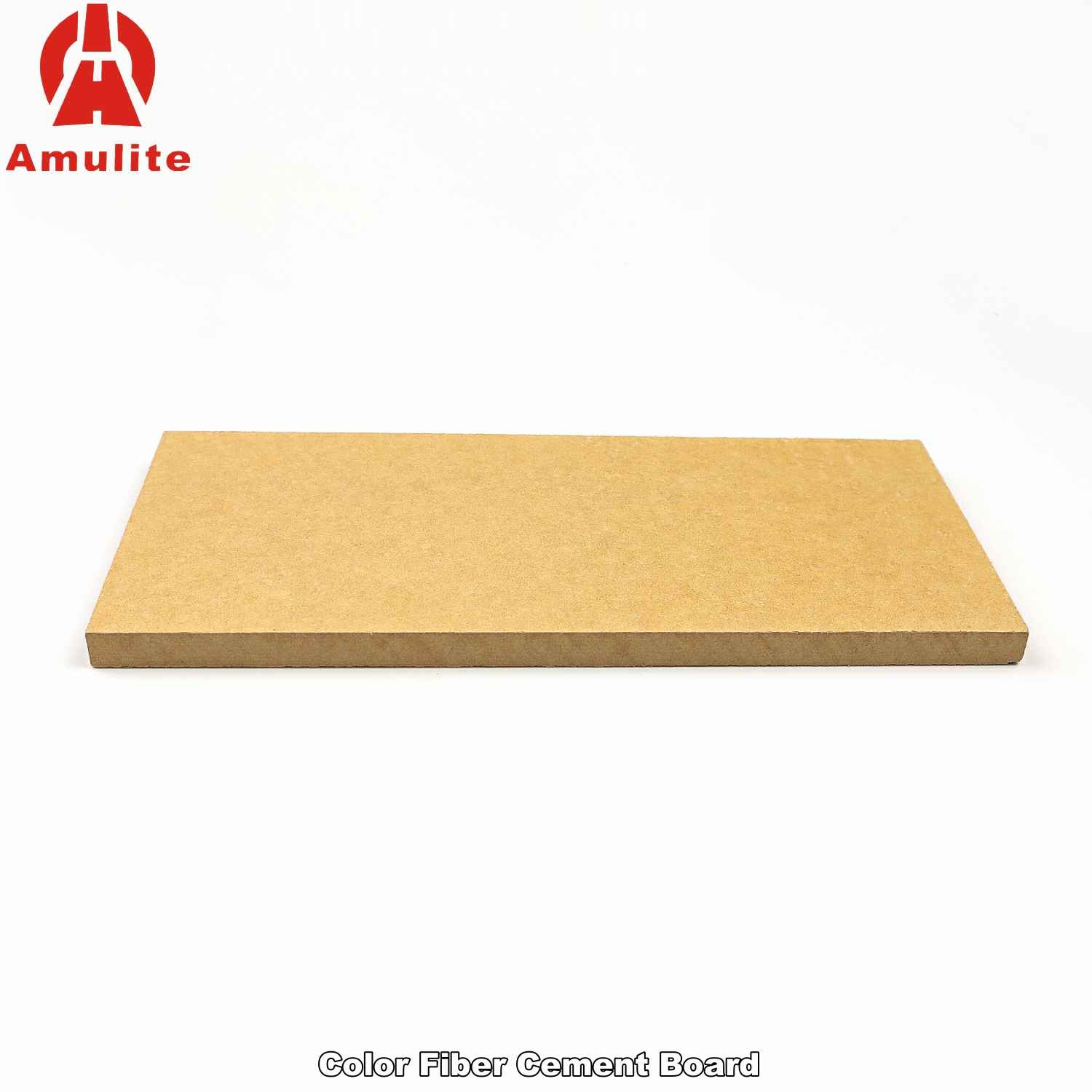

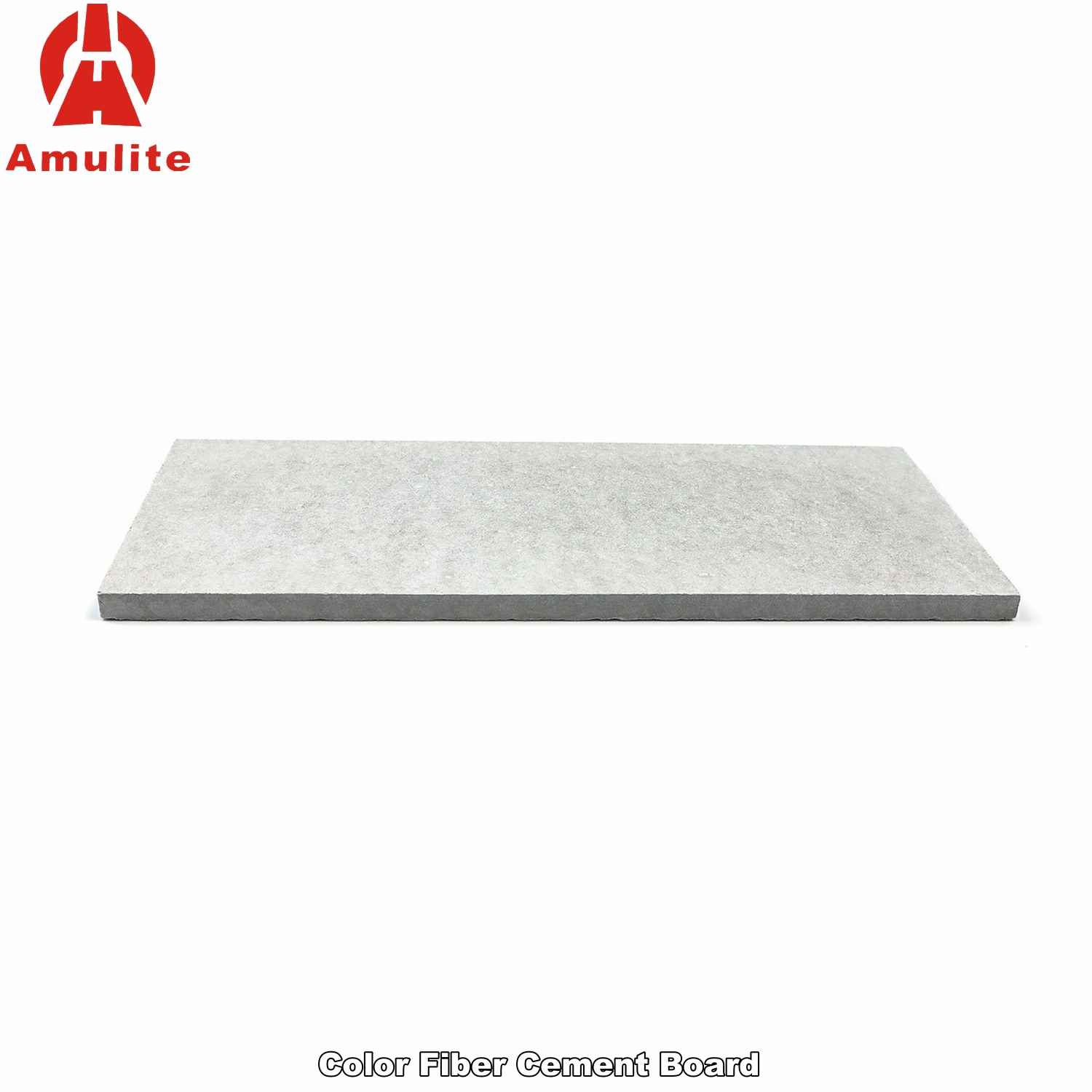

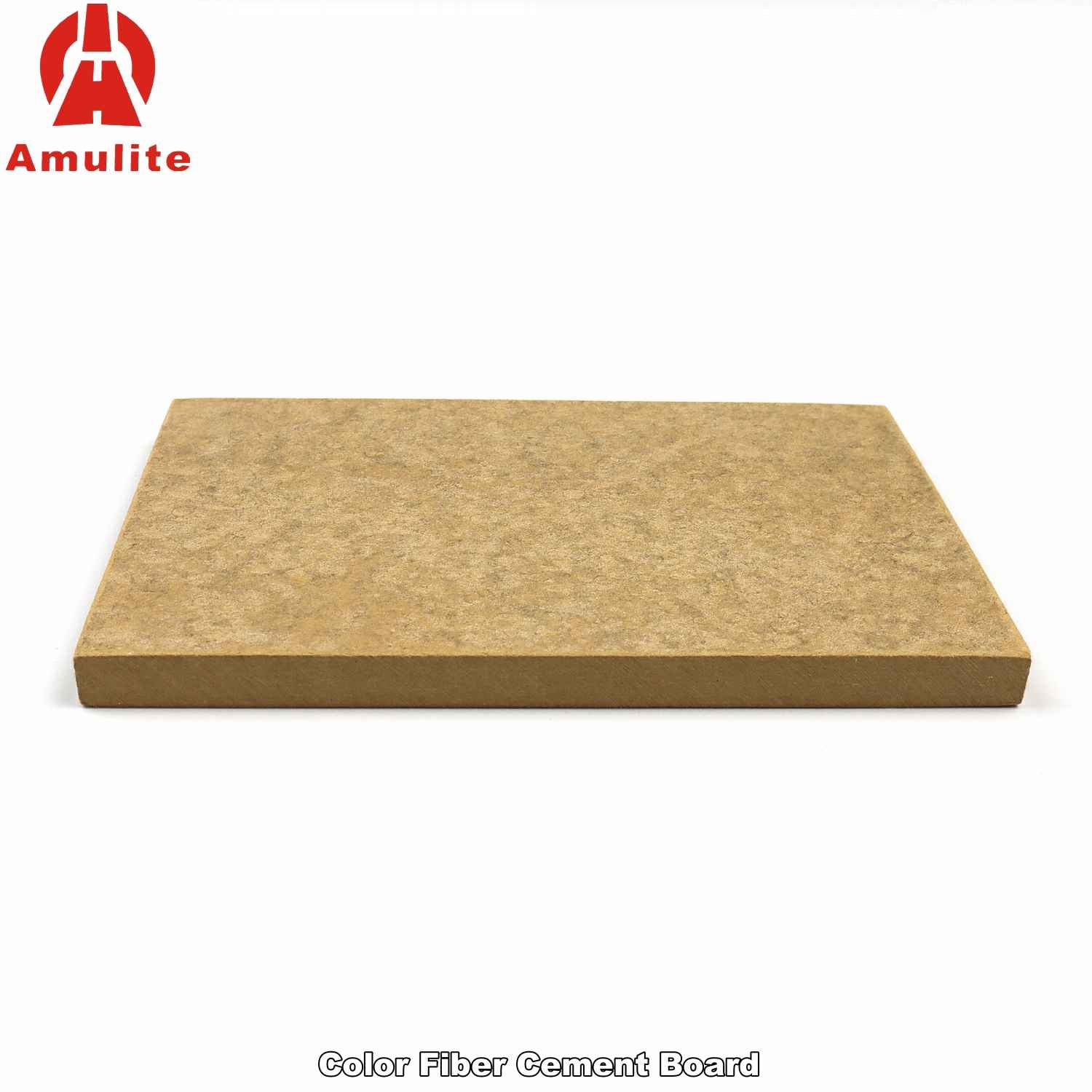

Amulite Dyed Color Fiber Cement Board

The Features of Dyed Color Fiber Cement Board

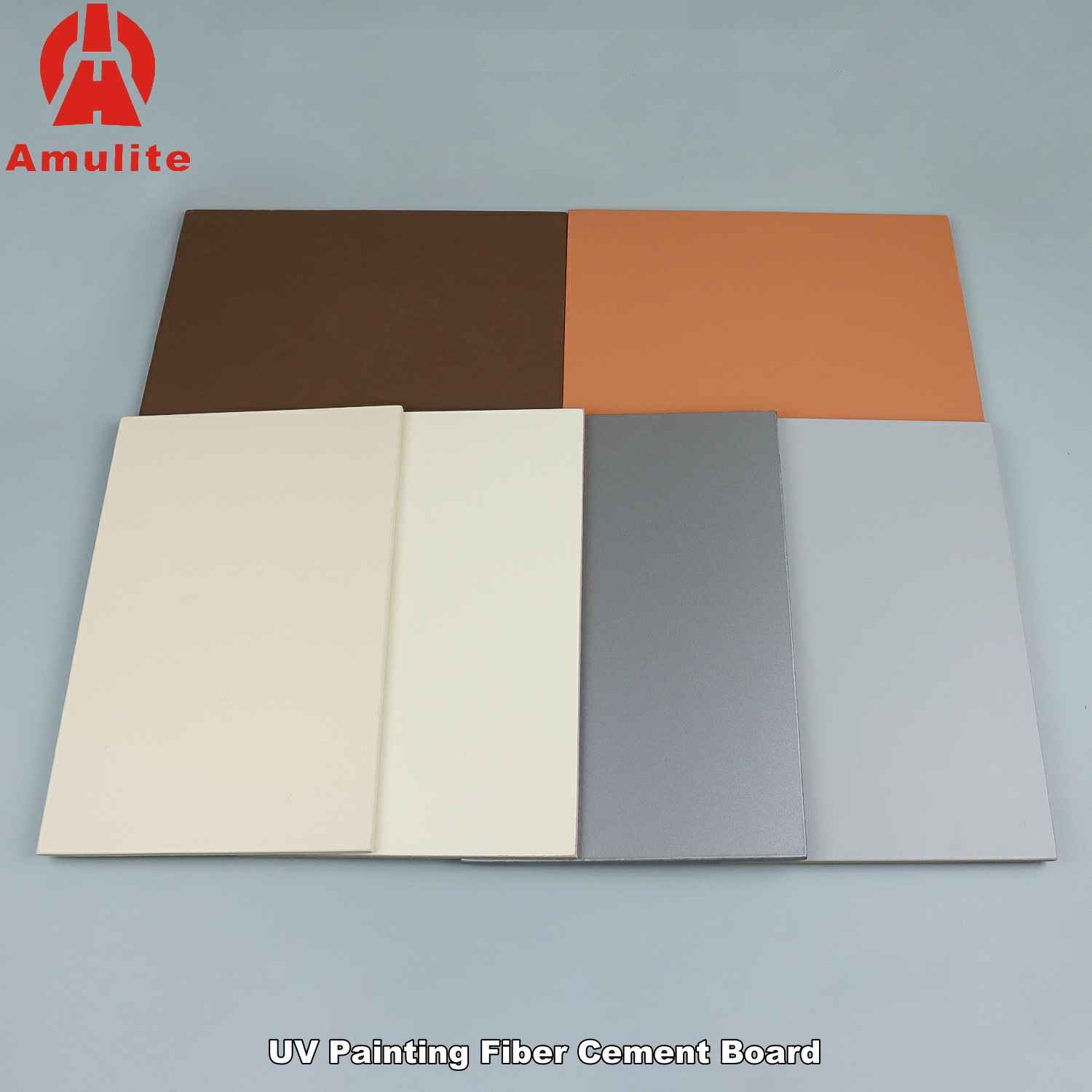

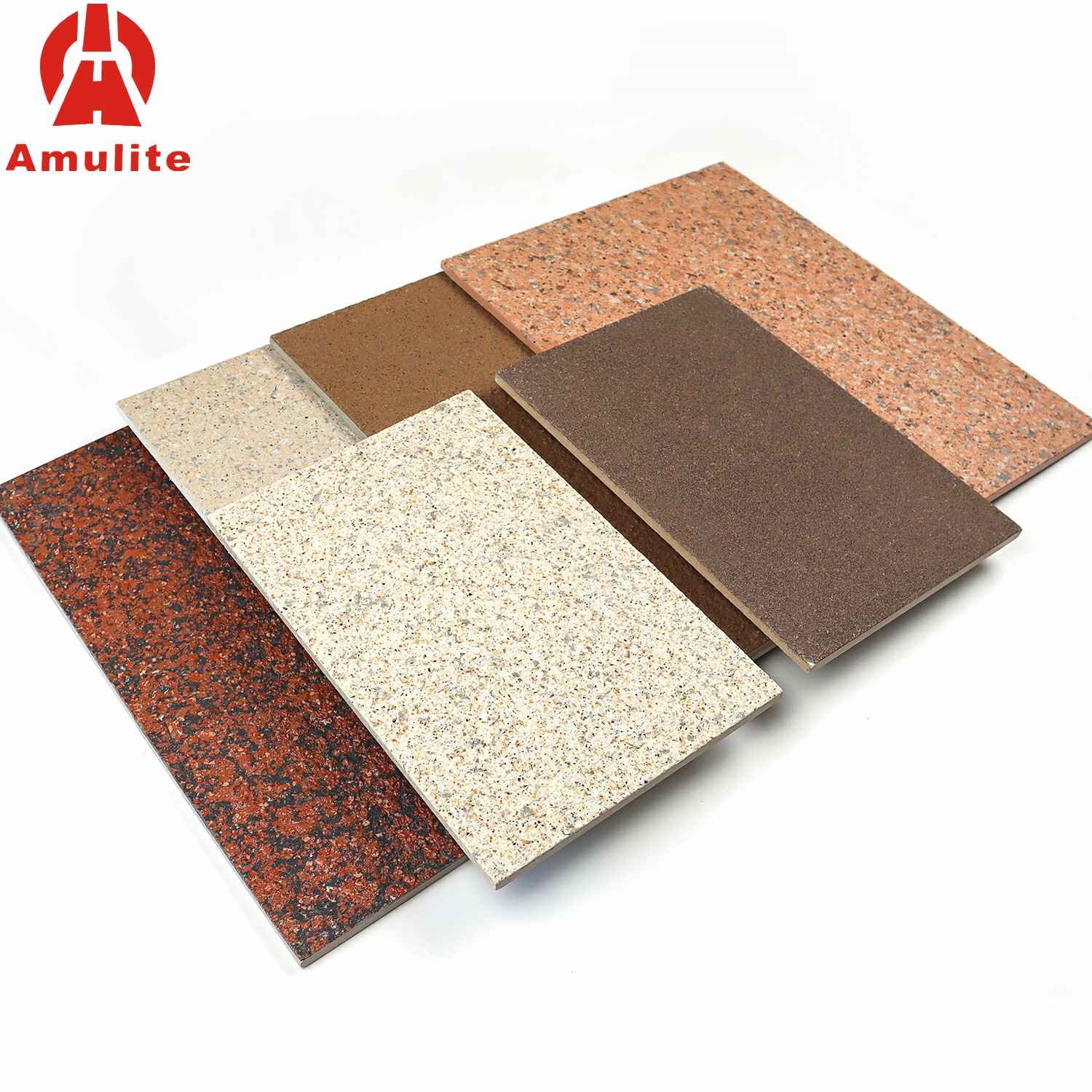

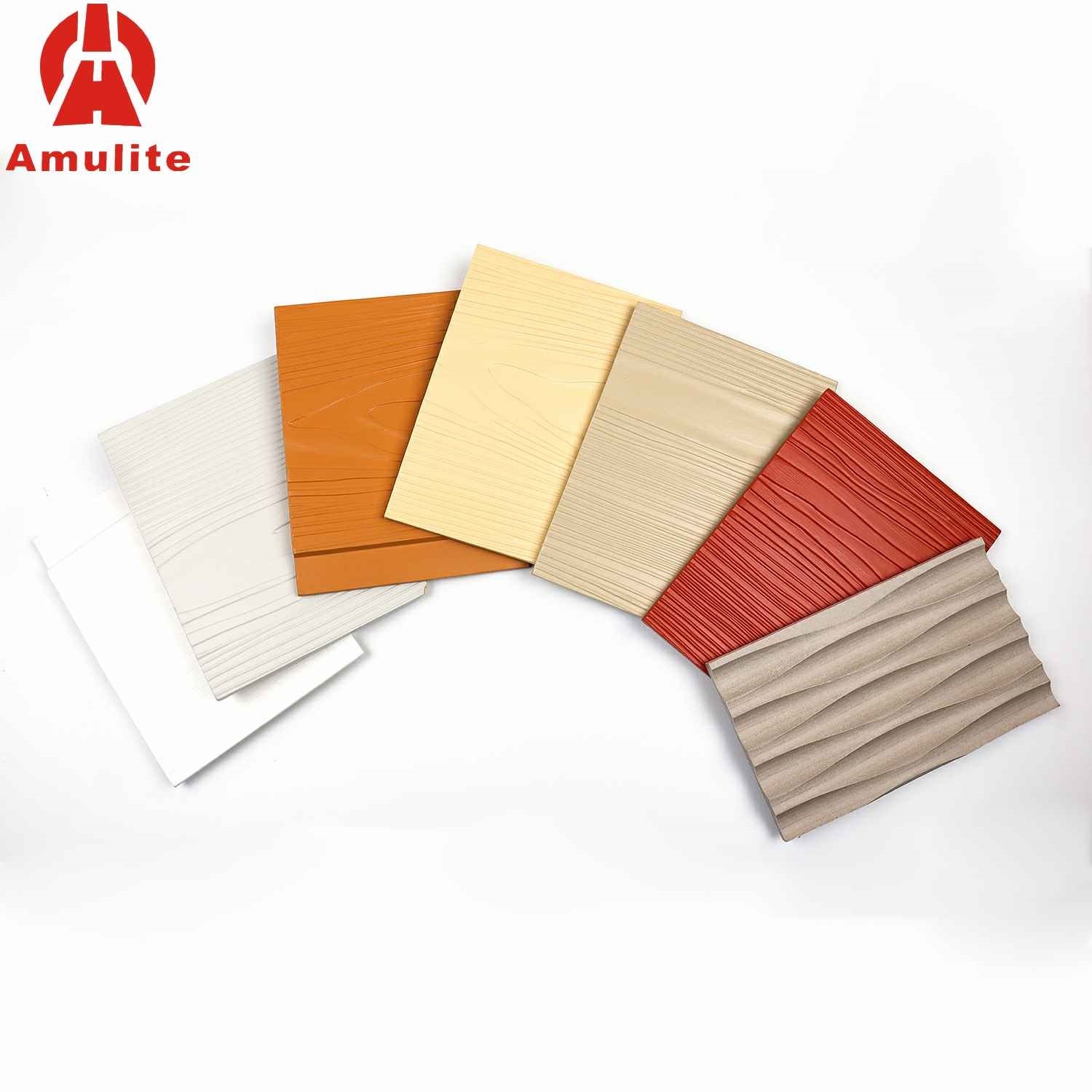

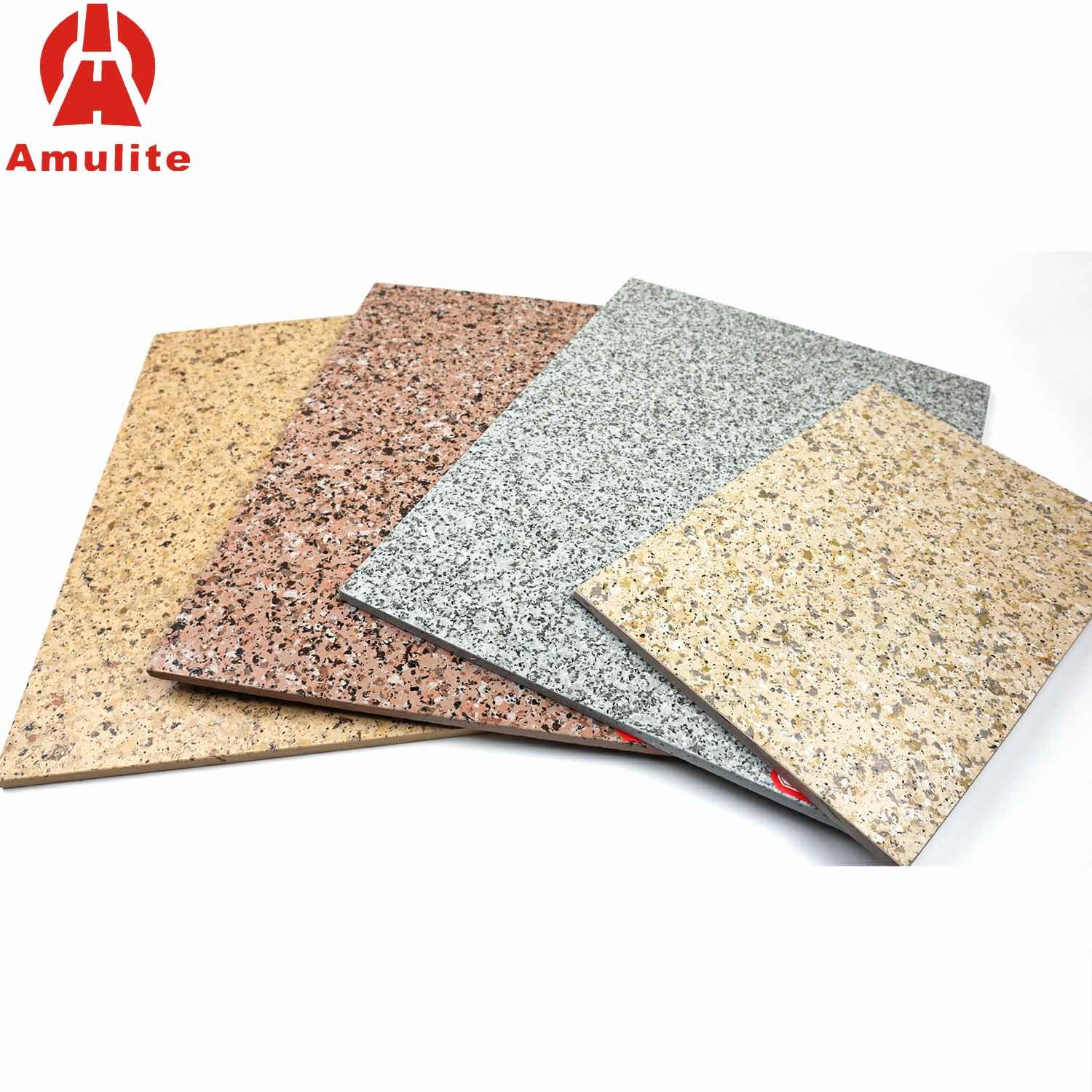

1.Dyed Color

Through The Crystallization Of Natural Minerals, The Color Is Innate, The Inside And Outside Are The Same, And The Color Is Rich And Varied, Which Can Meet The Diverse Architectural Design Requirements.

2.Easy To Cut

Amulite Dyed Color Fiber Cement Board Is Large In Size, Can Be Cut Into Various Sizes And Shapes Arbitrarily, Easy To Process (Perforation, Slotting, Engraving), Strong Plasticity, Rich In Expression, Can Provide Architects With Free Space For Creativity, And Endow Buildings With A Rich Expression On The Surface.

3.Easy To Install

The Installation Of The Plate Adopts The Dry Operation Method. Generally, Blind Rivets Are Used To Fix The Plate On The Keel Frame, Which Is Conducive To Shortening The Construction Period And Thus Reducing The Labor Cost.

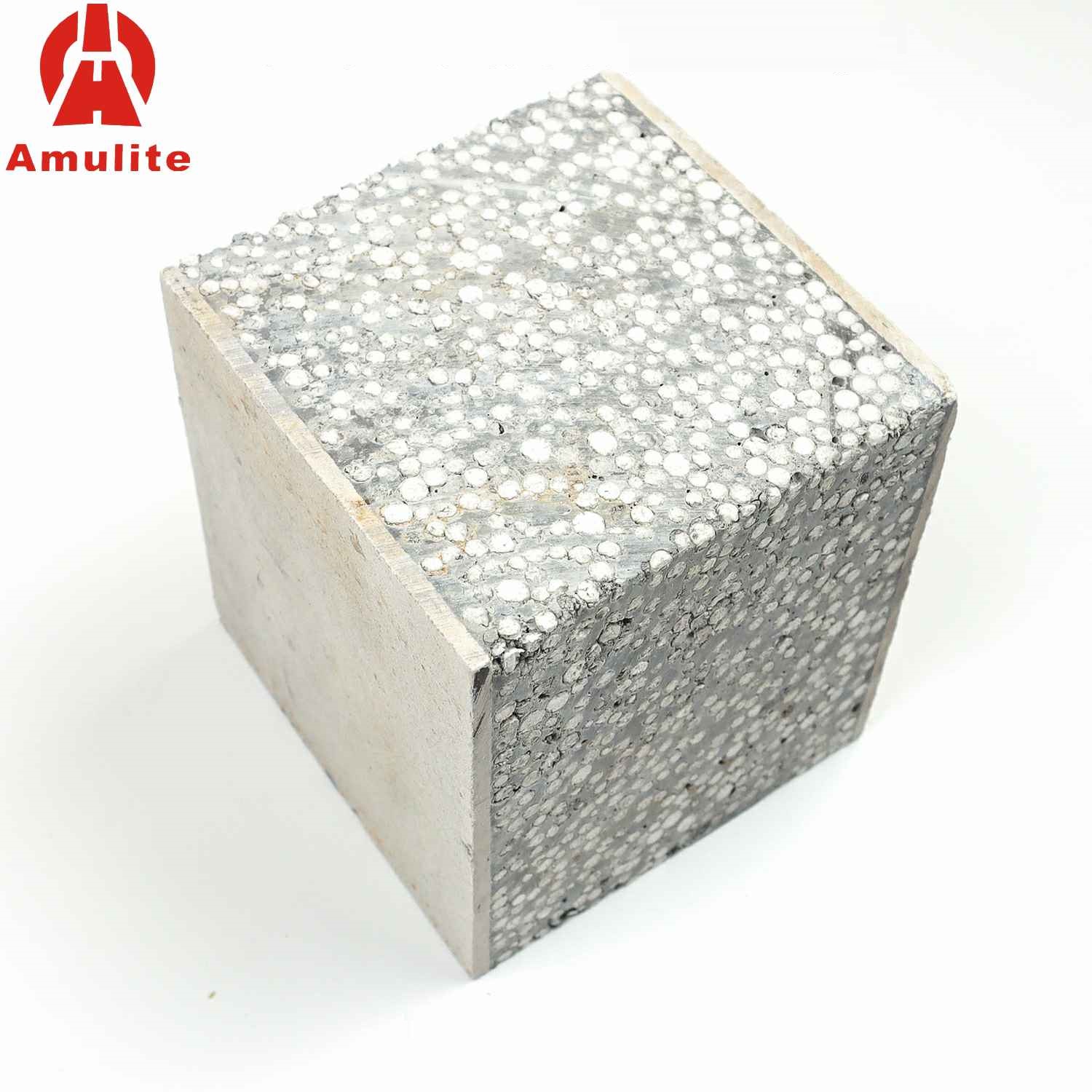

4.Green

Amulite Dyed Color Fiber Cement Board Uses Portland Cement, Selected Quartz Sand, Imported Plant Fibers, Natural Mineral Pigments And Other Natural Raw Materials, 100% Free Of Asbestos, Radioactive And Other Harmful Substances.

Technical Data

|

Item |

Unit |

Fiber Cement Board |

| Density |

g/cm³ |

0.9-1.5 |

| Flexibility |

MPa |

>9 |

| Thermal Conductivity |

w/m.k |

<0.29 |

| Impact Strength |

kJ/mm2 |

>3.0 |

| Screw Extraction Force |

N/mm |

<0.2 |

| Moisture Content |

% |

<10 |

| Vertical Flexural Strength |

MPA |

16-22 |

| Horizontal Flexural Strength |

MPA |

12-18 |

| Average Flexural Strength |

MPA |

14-22 |

| Delamination |

|

Non-Delamination |

| Moisture Movement |

% |

0.06 |

| Shrinkage Rate |

% |

<0.09 |

| Wet Expansion Rate |

% |

<0.19 |

| Non-Combustibility |

|

Comply with GB8624A class non-combustible material |

Amulite Dyed Fiber Cement Board Usage

Educational Building System

Medical Building System

Public Building System

Commercial Building Systems

Industrial Building Systems

Building Curtain Wall Exterior Wall Decoration

Building Decoration Interior Decoration

Special Construction Tunnel Decoration

Installation Method