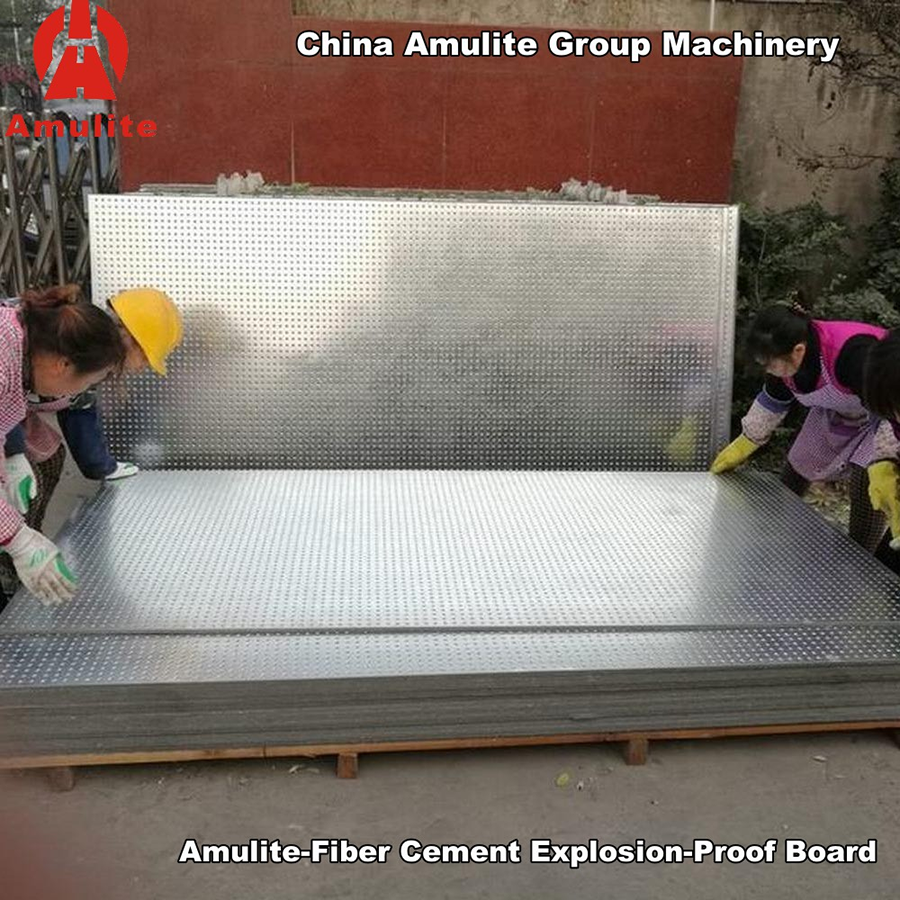

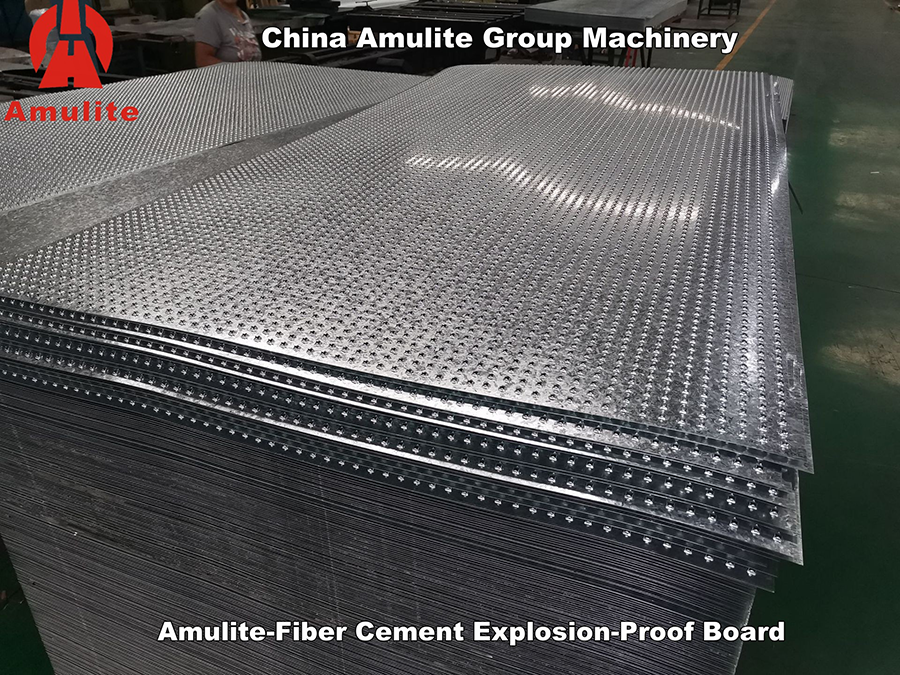

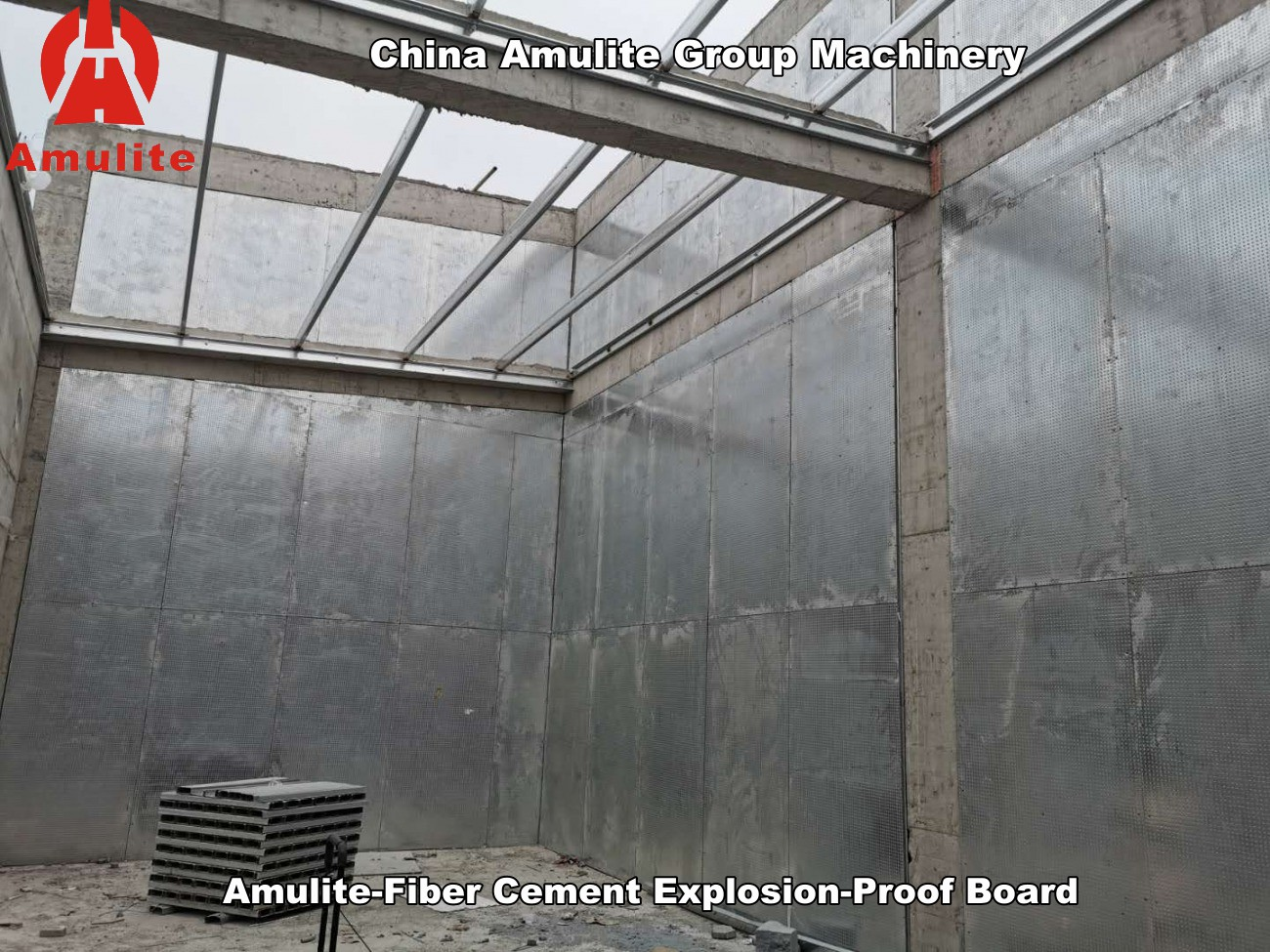

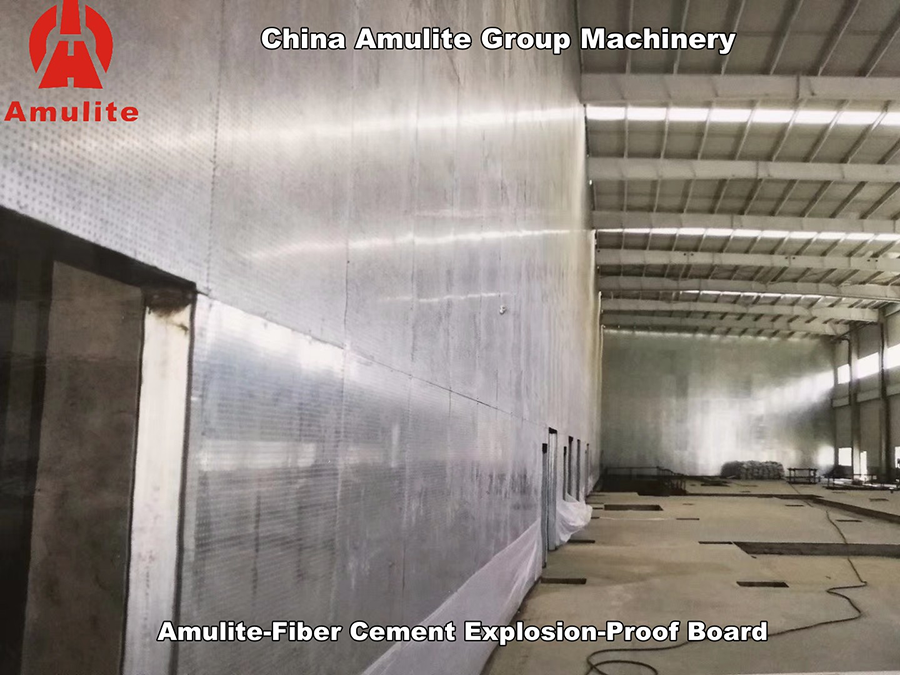

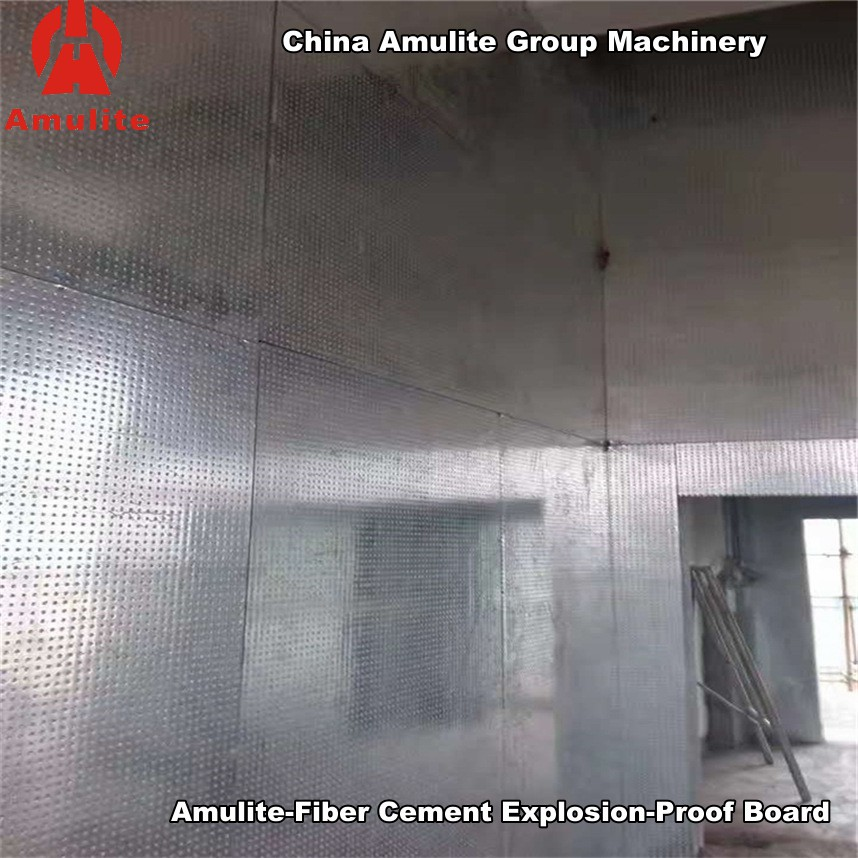

Fiber Cement Explosion-Proof Board

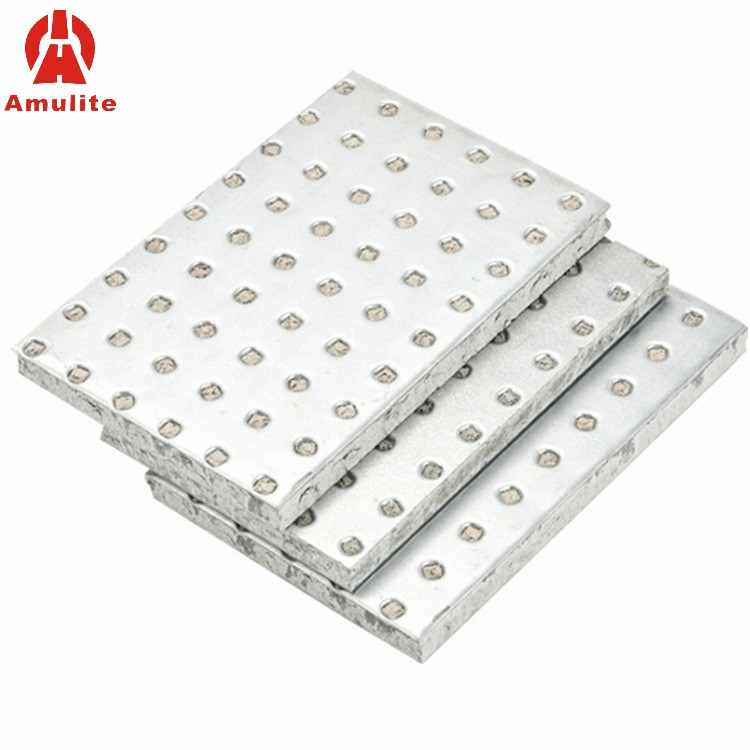

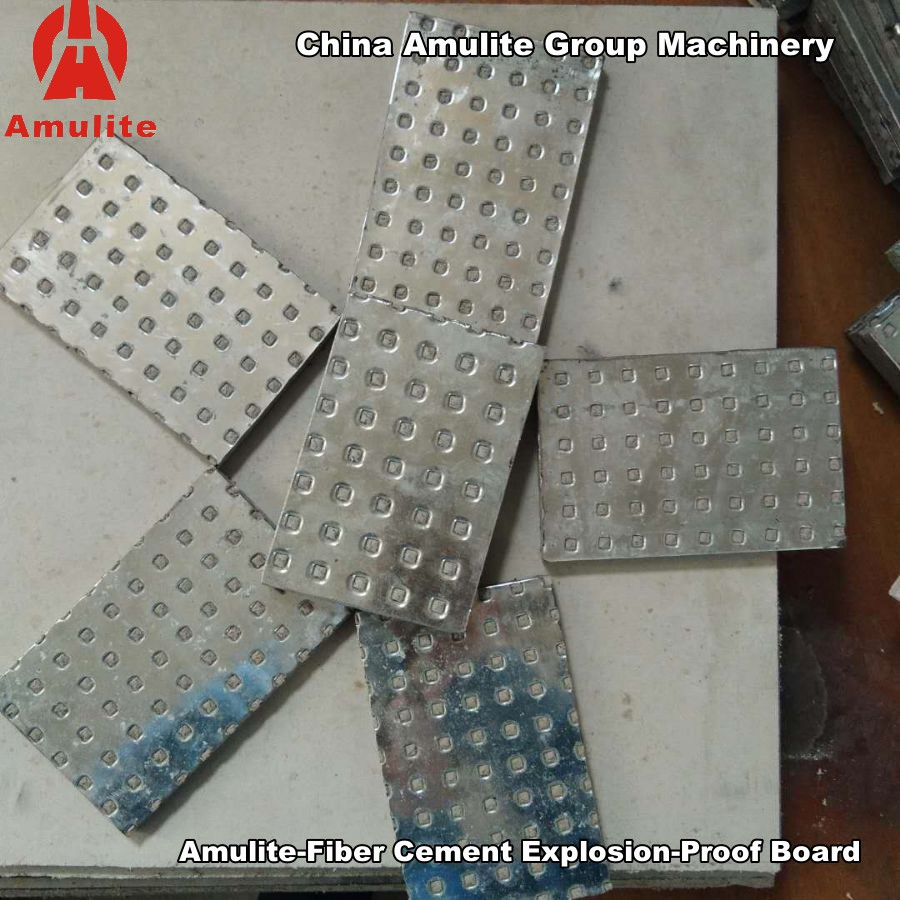

The Fiber Cement Explosion-Proof Board is a fire-resistant and explosion-proof material composed of reinforced fiber cement board surface pressurized galvanized steel material. Mainly used in explosion-proof partition walls, explosion-proof ceilings, explosion-proof smoke exhaust ducts, cable ducts, explosion-proof cable protection, explosion-proof doors and steel structure explosion-proof protection and other systems.

Features and advantages of Fiber Cement Explosion-Proof Board

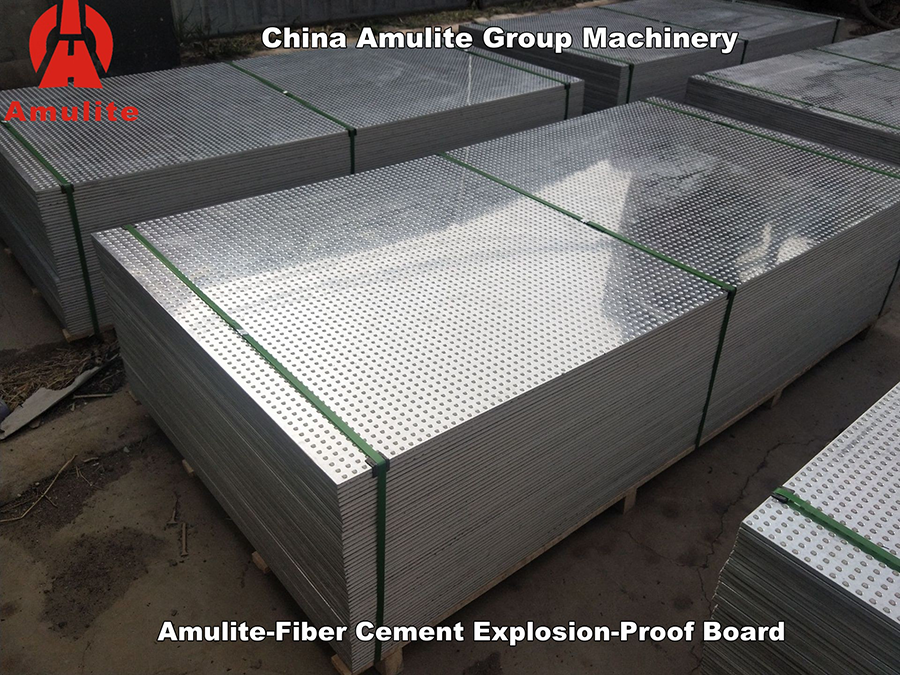

The Fiber Cement Explosion-Proof Board is researched and developed, and it has been recognized by the market. It has passed rigorous testing, It can be used for rampart, doors and ceilings, and the manufacturer can provide various specifications. The lightness, strength, impact, rice blast resistance, durability and special fire protection of the explosion-proof board enable firefighters to avoid a fire as much as possible and ensure the safety of life and property in society.

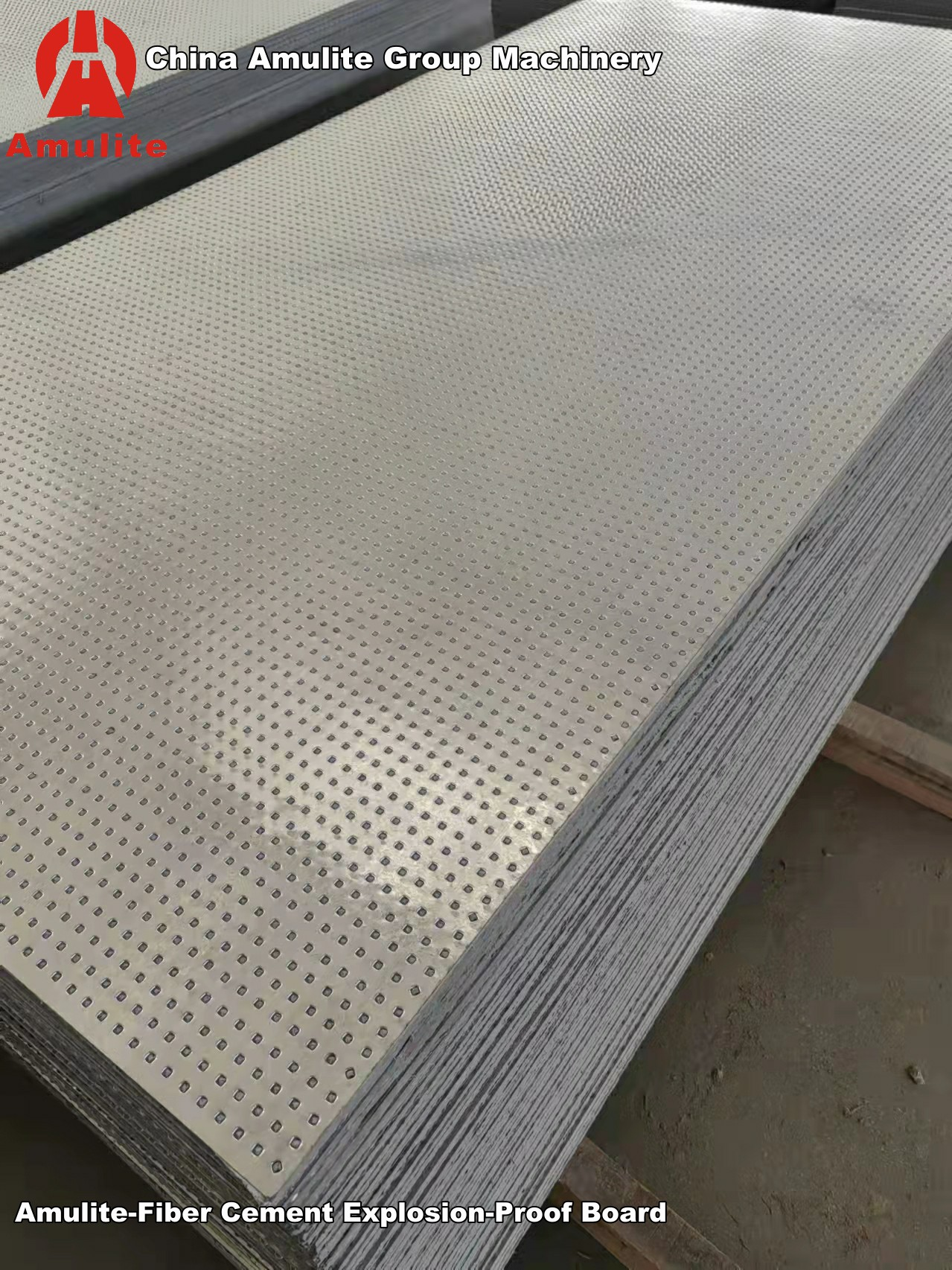

Flame resistance (combustion test lasting 4 hours), explosion resistance, impact resistance

Moisture and fire protection, earthquake resistance, light weight, corrosion resistance, large format

Weather resistance (does not change with temperature changes), high resistance, sound absorption, anti-freezing

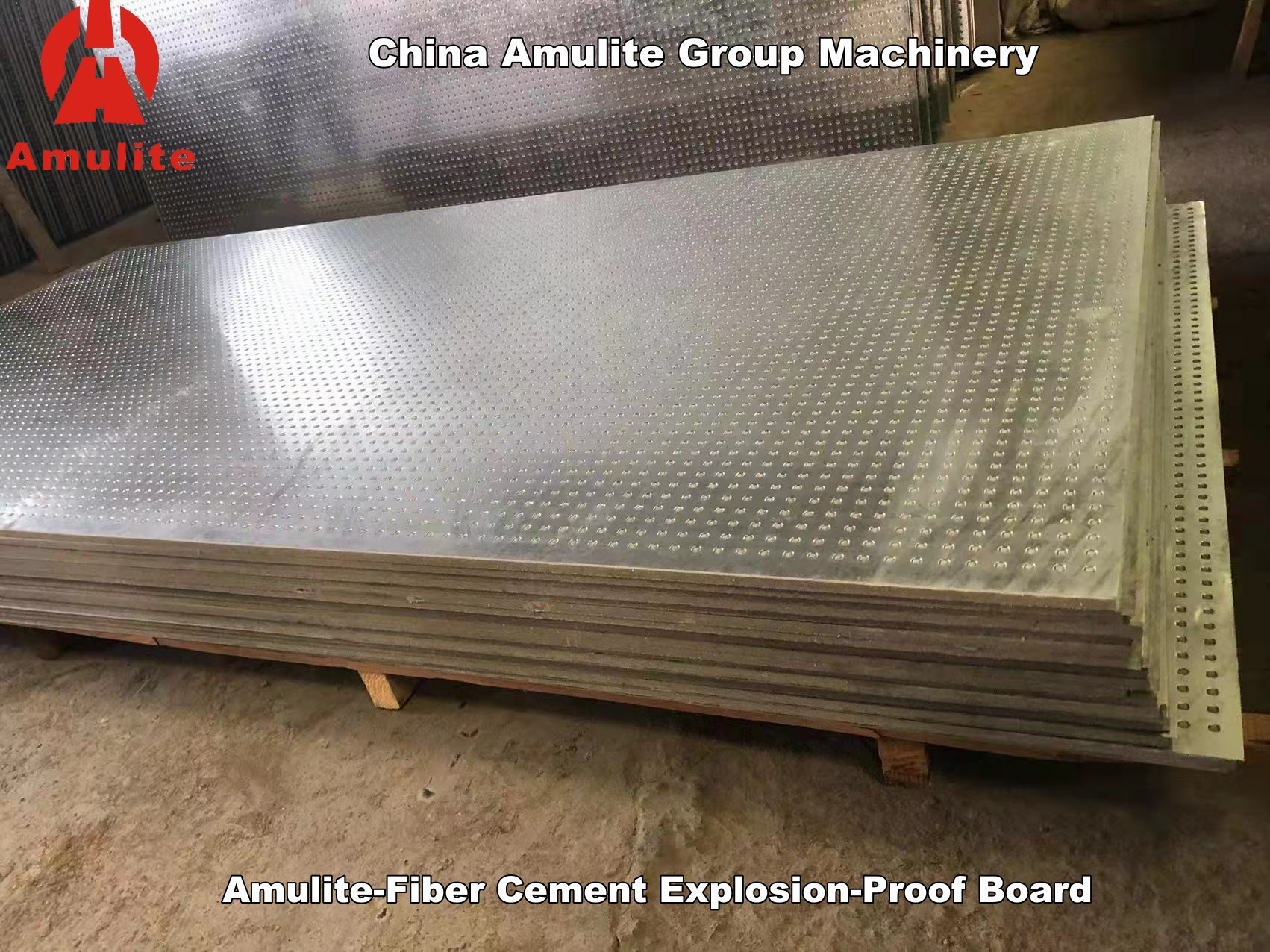

Application Area Of Fiber Cement Explosion-proof Board

The world is in various industries, including power stations, nuclear power, petrochemicals, pharmaceuticals, drilling platforms, warehouses, airports, railways, automobile factories, containers, waste recycling centers, data protection rooms, sports venues, military districts, laboratories, underground passages, Conveyor belt and subway facilities.

Application Part Of Fiber Cement Explosion-proof Board

Ventilation ducts, engineering protective covers, walls and partitions, flame retardant and smoke areas, cable channels,Explosion-proof and fire-resistant layer, tunnel

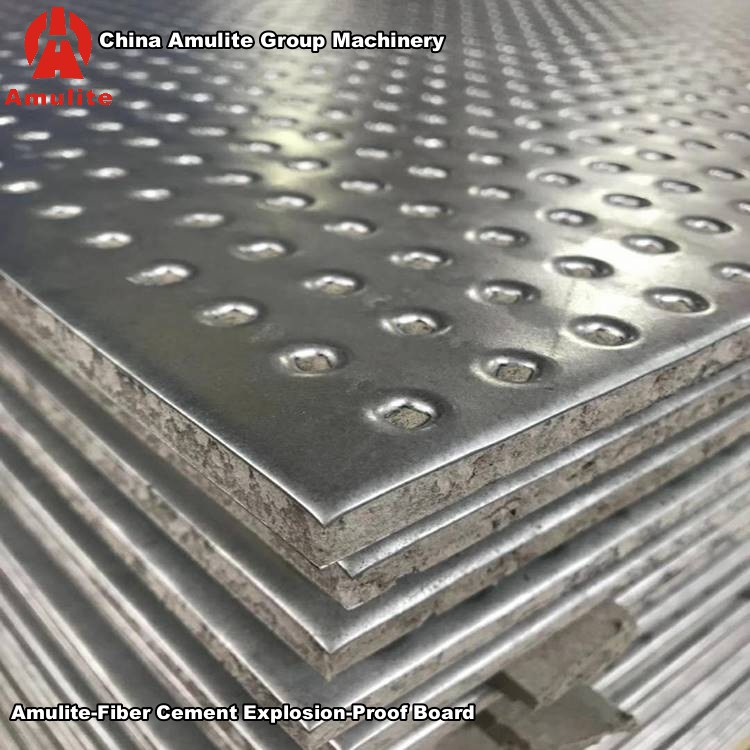

Fiber Cement Explosion-proof Board Test Data

| Specification | 6.0mm | 9.5mm |

| According To DIN4102 Building Material Grade | Non-combustible A1 Level | |

| Temperature Range | 400---1000℃ | |

| Density | 2.8g/cm3 | 2.2g/cm3 |

| Compressive Strength | 60N/mm2 | |

| Bending Strength | 109N/mm2 | 80N/mm2 |

| Tensile Strength | 32N/mm2 | 30N/mm2 |

| Elastic Module | 55000N/mm2 | 4000N/mm2 |

| Conductivity | 0.55W/mK | |

| Sound Absorbing(110-3150Hz) | 28dB | 30d |

| Weight | 16.8kg/m3 | 21kg/m3 |

| Moisture Content | 6% | |

| PH | 12 | |

| Storage Conditions | Dry Room | |

| Standard | 1200*2500(+-3mm) | |