Fiber cement board is a building material typically used as siding or trim. This material was designed to provide a product that is durable and able to withstand climate extremes. Fiber cement boards require little maintenance and offer several advantages over traditional siding materials such as vinyl or wood.

Manufacturing

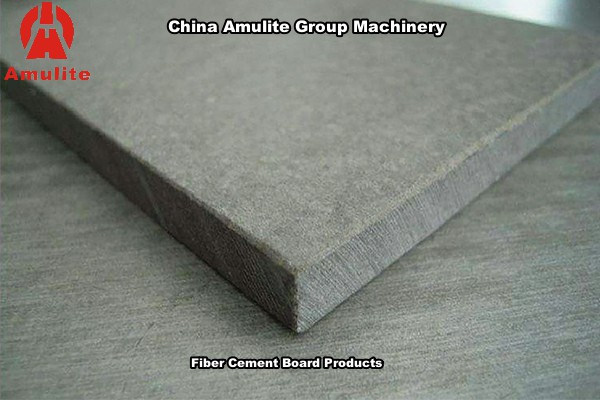

Fiber cement board consists of cement, sand, and cellulose fibers that are manufactured in layers to form sheets of varying thicknesses. The boards are manufactured using a process called autoclaving, which uses high-temperature steam curing to form the board and to increase the strength and stability of the sand and cement. The cellulose fibers help to prevent cracking. A wood grain pattern is added to the surface of siding boards before the material is cured.

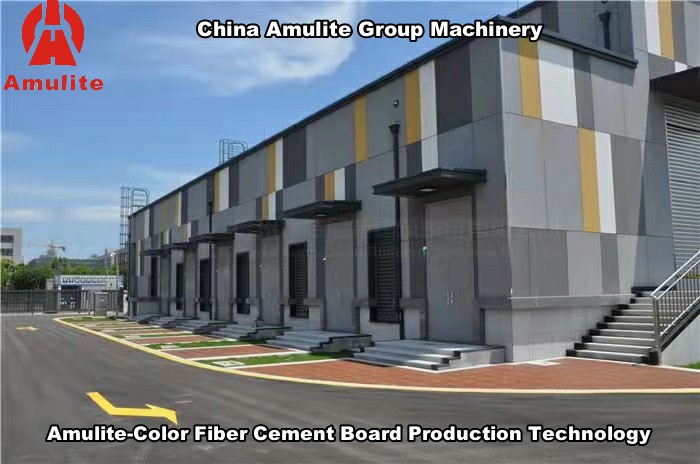

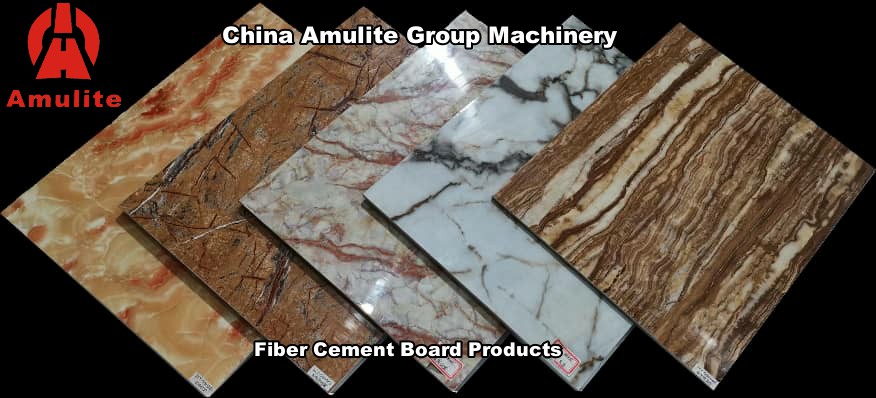

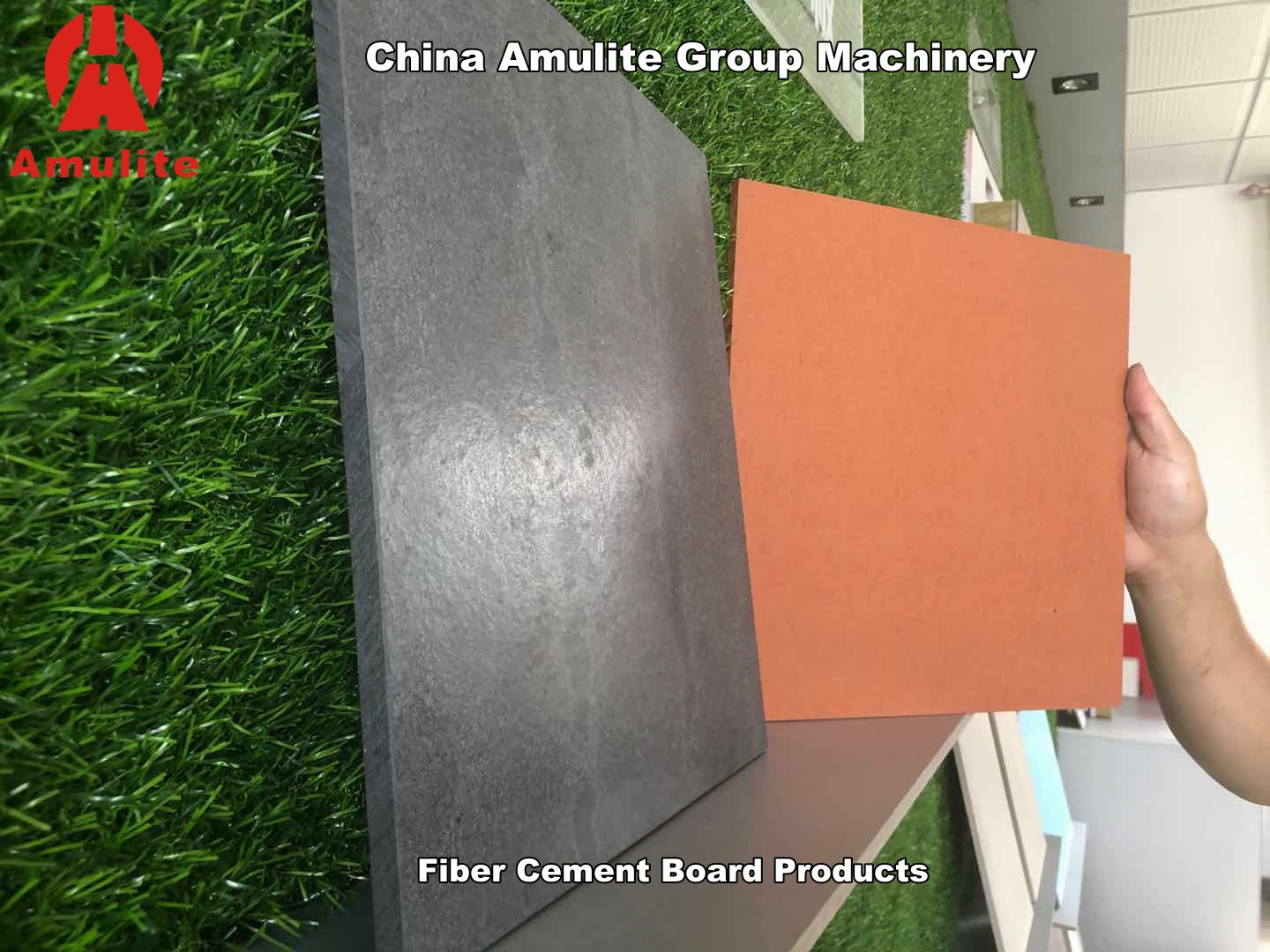

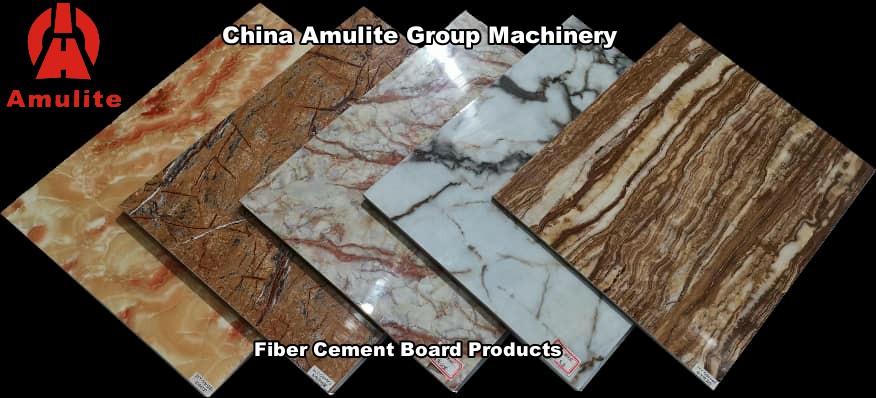

Design Options

Fiber cement board is available in a variety of colors. It is also made in several profiles so that it appears similar to traditional siding, like Dutch lap or beaded. Because it isn’t bendable, fiber cement siding is formed at the factory and can be shaped for use as shingles or trim.

Maintenance

Fiber cement boards are strong and designed to hold up under extreme climates where intense sunlight, moisture or wind is common. This material is also resistant to fire, insects and rotting. Fiber cement board doesn’t require painting. Boards can be colored at the factory to suit your design needs. If you do choose to paint this material, it will soak it up well, and with quality paint it won’t peel or chip as painted vinyl or steel does. It is designed to be a low-maintenance building material, but it does require regular cleaning and inspecting caulked joints around windows and doors yearly.

Advantages

Fiber cement board doesn’t warp or fade, which vinyl can do. It can withstand ultraviolet rays and is impenetrable by insects and birds. It doesn’t dent or bump under direct impact and will not become brittle in cold temperatures. Fiber cement boards can be used in historical renovations, where other cladding materials are not allowed. Because of their long life, fiber cement boards also cut down on repair and maintenance costs. Many warranties guarantee the material for seven years or longer.

Disadvantages

Fiber cement board can be difficult to work with. It has a high dust content, so when cutting and working with this material, a face mask is necessary. It is heavier than materials such as vinyl, and can break if carried flat. Caution should be used when transporting or carrying fiber cement boards because the edges and corners will chip easily before installation. The surface to which you’re installing the boards has to be clean and smooth because the sheets of fiber cement board will not hide bumps as other siding material will do.

Post time: Jan-05-2023